Phoronix: Linux Might Drop Fieldbus Support For Industrial Systems With No One Maintaining It

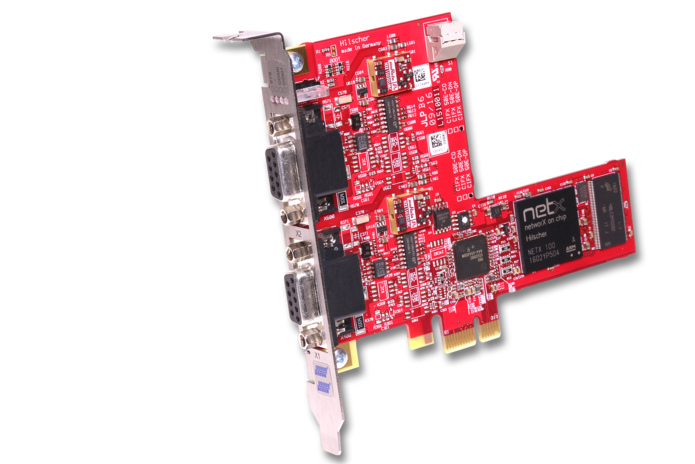

Merged back in 2019 was the Fieldbus system for connecting different systems/components/instruments within industrial environments. Five years later the code isn't being well maintained and looks like it will be on its way out the door if no one steps up to better maintain this driver support for industrial systems for process automation...

Merged back in 2019 was the Fieldbus system for connecting different systems/components/instruments within industrial environments. Five years later the code isn't being well maintained and looks like it will be on its way out the door if no one steps up to better maintain this driver support for industrial systems for process automation...

Comment